We take high-spec, tight-tolerance and fast-turnaround challenges and turn them into the exact injection mold or technical plastic parts you require.

Fast turnarounds

Rapid is our first name.

High-spec challenges

We have the right engineers, equipment and experience.

Tight tolerances

Tolerances so tight, there’s no room for doubt.

Every tool sampled

3+ hour production runoffs for proven performance.

A reliable partner

Here for you since 1997.

From engineering and tooling to process development and cleanroom molding, we offer end-to-end capabilities.

Learn moreInjection molding

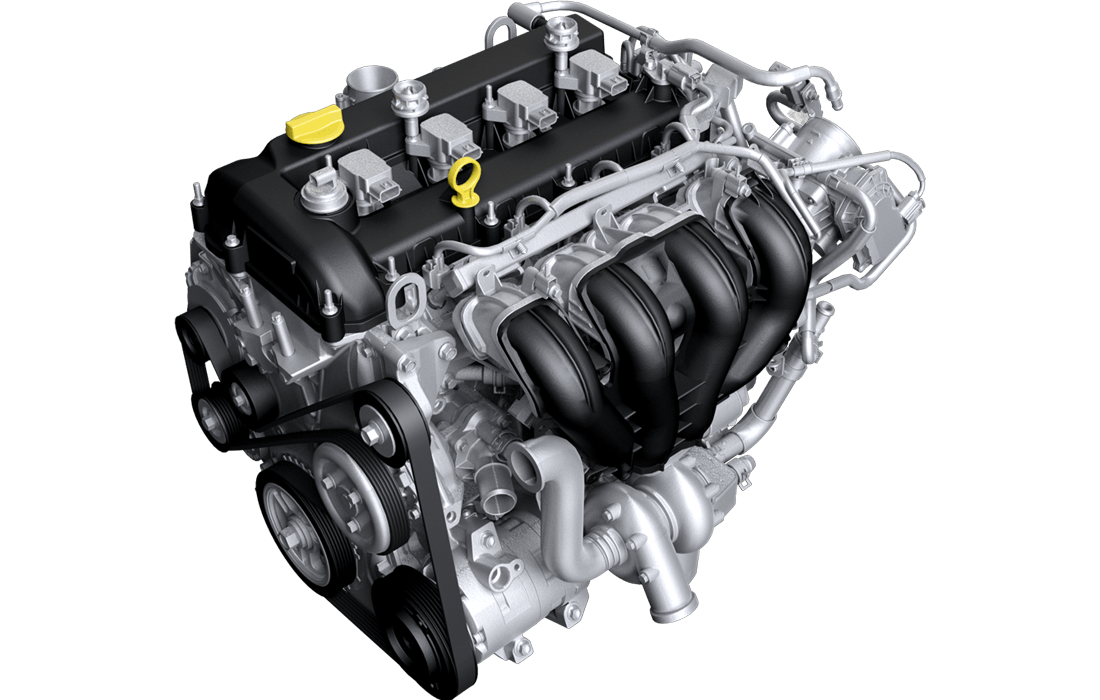

You know us for our meticulous tooling. Now discover our plastic injection molding capabilities that deliver precision and performance for your technical applications.

Creating medical parts with surgical precision and ISO 8 clean room capabilities.

Experts at working with fiber optics tolerances since 1997.

We partner with some of the biggest brands to provide engineering, tooling and production that drive performance.

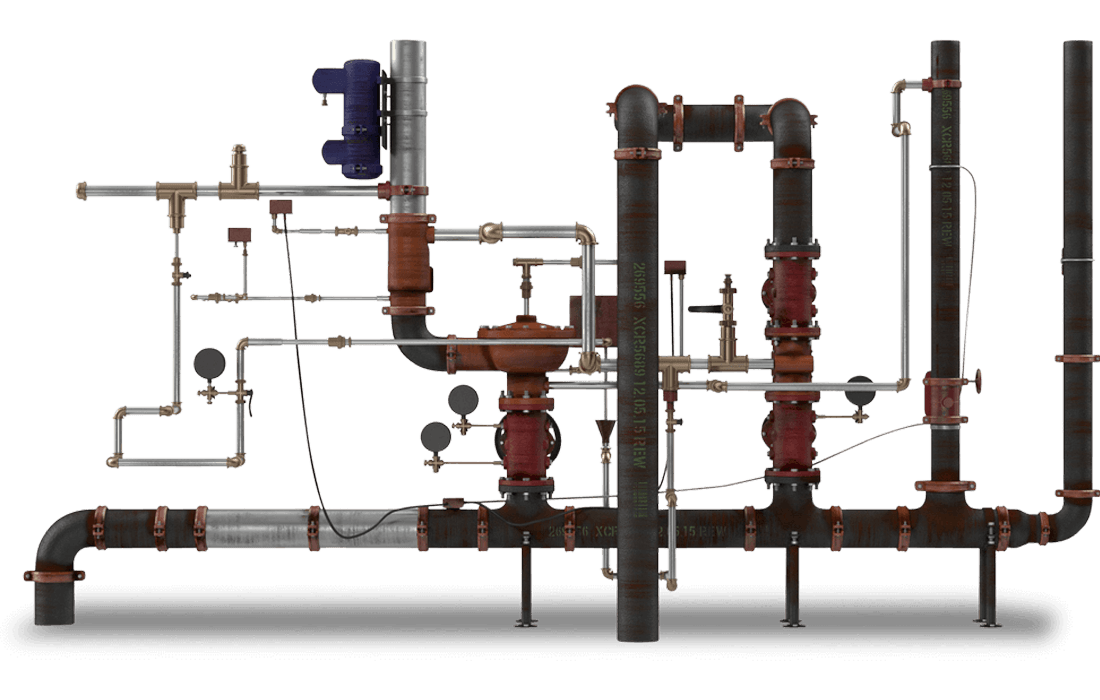

We bring value by delivering exceptional sprinkler parts at the right price point.

In an industry that’s always innovating, we can reduce your time to market (TTM).

Leading OEMs in every kind of space bring us their high-spec challenges.

“Outstanding project management and customer service, coupled with their in-house processing expertise, make Rapid the choice for my most challenging tooling projects.”

– Senior Tooling Engineer

Fiber Optic/Telecommunication Industry

“Their level of knowledge and fast responsive service and support help us achieve our goals effectively and efficiently.”

–Sr. Tooling/Process Engineer

Medical Device Industry

“Our business relies on the accuracy of our finished parts and we trust Rapid Production Tooling to deliver that accuracy.”

– VP Engineering

Manufactured Parts Company